Mochini oa ho Etsa Masela a sa Lohiloeng oa SS

Lebitso la sehlahisoa:

SS-3200 PP SPUNBOND NONWOVEN FABRIC EA MACHINE

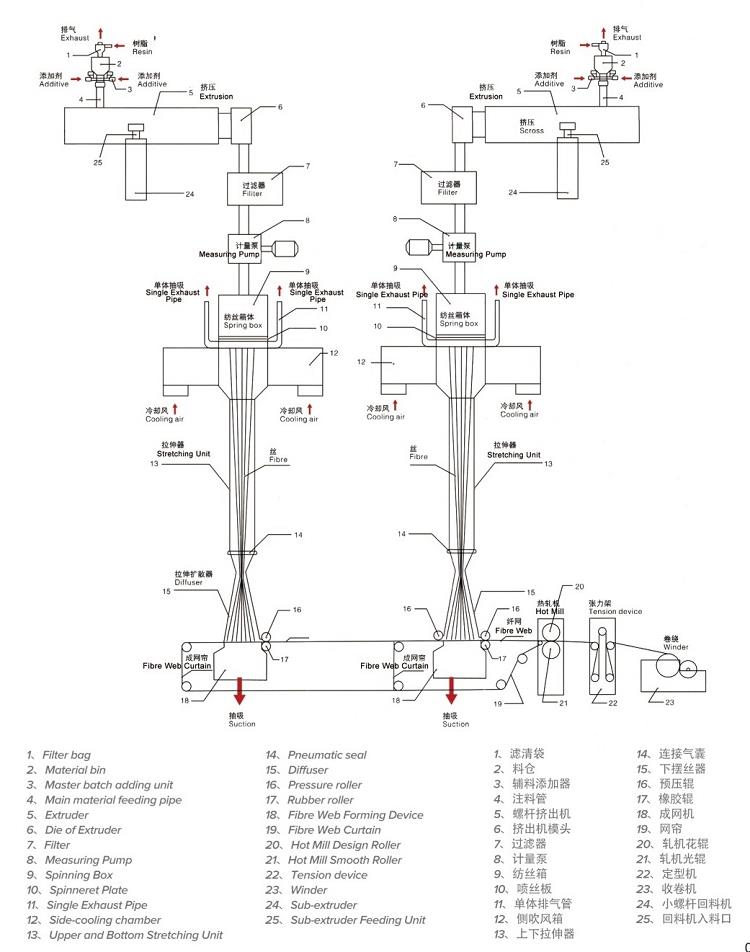

1.ts'ebetso ea ho phalla:

Ho fepa → Ho qhibiliha ha Extrusion → ho sefa → metering → ho ohia → Ho pholisa → Ho otlolla → Ho hasana ha webo → Ho tlamahanngoa ha mocheso → ho seha → ho bokella

2. Sebopeho sa sehlahisoa:

2-1 Product PP spunbonded nonwovens

2-2 Product bophara: 3200mm (ho qetela nonwoven sehlahisoa)

2-3 Sehlahisoa sa gram 14-120 g / m2

2-4 Filament titer: ≤2.5 Denier

2-5 Matla a tlhahiso: 18T / Letsatsi (E Thehiloe holim'a lesela≥40g / m2 )

3. tlhahiso ea thepa e tala

3-1 Lethathamo la ho qhibiliha (g/10min) 20-40

3-2 ntlha ea ho qhibiliha.0C) 165

3-3 Tekanyo e tšoanang ea molek'hule (%)> 95

3-4 Karolo e putsoa (PPM) <200

4. Lisebelisoa

4-1 Motlakase: 1312KW bakeng sa mohala o felletseng, matla a sebetsang: 495KW

| SN | Lisebelisoa tsa mantlha tsa motlakase | Matla a ho sebetsa | Coefficient |

| 1 | Fepa Fepang | 5.5KW×2 | 0.5 |

| 2 | Metara ea papali e hloahloa | 0.75 KW×6 | 0.4 |

| 3 | Extruder | 110 KW×2 | 0.4 |

| 4 | Pompo ea Metering | 5.5 KW×2 | 0.5 |

| 5 | Sistimi ea potoloho ea oli e chesang | 4KW×4 | 0.6 |

| 6 | Websaete ea pele le preheating roller | 36 KW×1 | 0.3 |

| 7 | Khalendara | 22 KW×2 | 0.5 |

| 8 | Sistimi ea potoloho ea oli | 5.5KW×1 | 0.6 |

| 9 | Rewinder | 15KW×1 | 0.6 |

| 10 | Slitter | 11KW×1 | 0.3 |

| 11 | Sefutho se phodileng se ka thoko | 75KW×3 | 0.4 |

| 12 | Sefahla-mahlo | 55KW×1 | 0.50 |

| 13 | Sistimi ea ho pholisa | 100KW×1 | 0.5 |

| 14 | Toulo ea ho pholisa metsi | 15KW×1 | 0.6 |

| 15 | Calciner | 38 KW | 0.3 |

| 16 | Mohloekisi oa Ultrasonic | 2 KW | 0.4 |

| 17 | Sebaka sa motlakase | 2 KW | 0.2 |

| 18 | Mabone a workshop | 10KW | 0.5 |

| 19 | Sistimi ea ho futhumatsa | 492 KW×1 | 0.4 |

| 20 | Sehlahisoa sa recycle extruder | 18.5 KW×2 | 0.3 |

4-2 Metsi: 160m3/ hr ho potoloha metsi, tšebeliso ea 1T / letsatsi

4-3 Moea o hatelitsoeng: 1m3/min.khatello ea 0.8Mpa

4-4 Karolo e ikarabellang ea bareki:

Mohaho oa A.Plant: 25x12x11 M

B. Matla a romelloang ho khabinete e 'ngoe le e 'ngoe e laoloang

C.Metsi a romelloa lisebelisoa le mabone Configuration ea semela

D. The stuffs, hoisting thepa le ho kenya thepa le thepa e hlokahalang

nakong ea ho kenya.

(Moreki o lokela ho fana ka bolulo le moputso oa litsebi tsa mofani oa thepa.)

5. Setšoantšo se qaqileng

|  |  |

|  |  |

6.Tshebeletso

Tšebeletso:

A.L tshehetsa tshebeletso ya bareki ba 24hoursAday,7dayworkwork,Leha ho ka etsahala

e arabetsoe ka hare ho1hora pele ho thekiso le ka mor'a thekiso.

WeBelievethatonly:BestQualityMachineWithInnovativeIdeasand ExcellentAfter-saleService:”e tla kopana le litlhoko tsa hao tse khethehileng.

7.Molemo

Tšebeliso ea masela a Nonwoven:

(1) Ts'ebeliso ea bongaka le bophelo bo botle: sutu ea ts'ebetso, seaparo, maske sefahleho, leleiri, lesela la bohloeki, sehlahisoa sa bohloeki se lahliloeng.etc;

(2) Mokhabiso oa lapeng: mokotla oa mabenkele, lesela le koahelang lebota, lesela la tafole, lakane ea bethe, bedspread.etc;

(3) Lining bakeng sa liaparo kapa lieta: lera, sekhomaretsi interlining, lieta lesela.etc;

(4) Ts'ebeliso ea temo: Sekoaelo sa ts'ireletso, sekoaelo sa booki.etc;

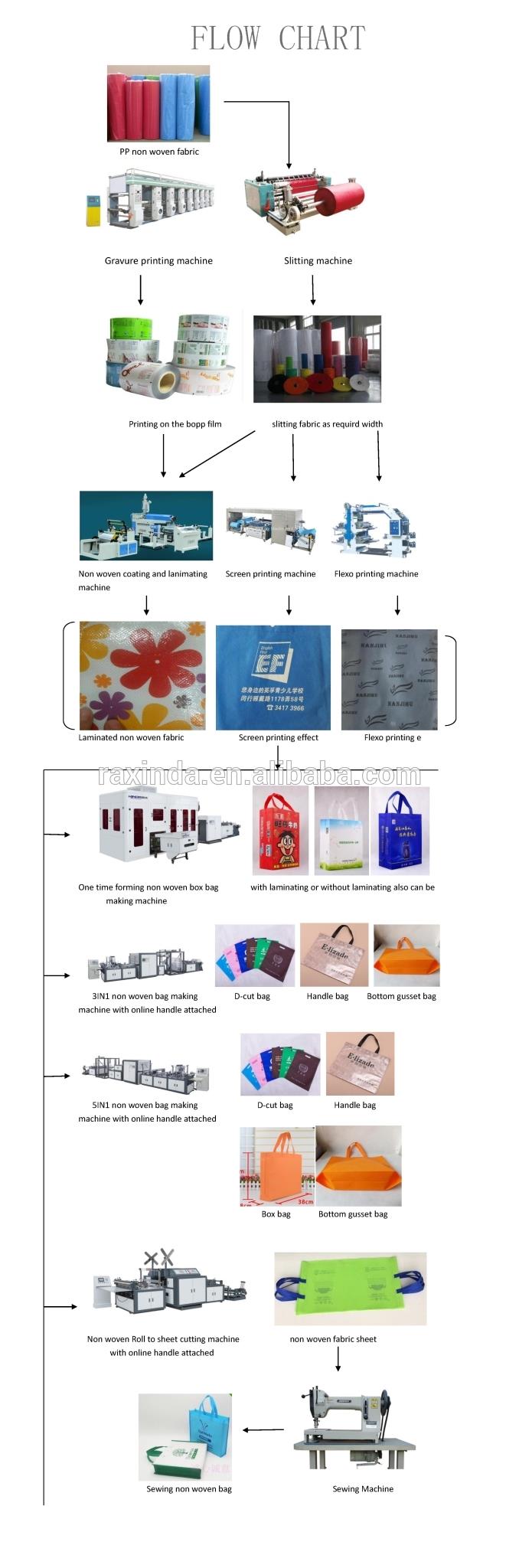

Mochini oa boikhethelo![]() thepa e sa tsitsang bakeng sa mokotla oa U-cut

thepa e sa tsitsang bakeng sa mokotla oa U-cut

Mochini o kopanyang

Mochini oa mantlha o sa lohiloeng

Tsamaiso ea boleng bo botle e ela hloko lintlha tsohle tsa ts'ebetso ea tlhahiso ea lisebelisoa

Re thehile litekanyetso tse thata tsa taolo ea boleng ba likarolo, likarolo tse ling tsa bohlokoa li sebelisa lihlahisoa tse tsebahalang tsa kantle ho naha ho etsa bonnete ba hore o sebetsa hantle haholo mochini o mong le o mong, sekhahla se tlase sa palo, ho tšoarella, ts'ebetso e bonolo le e bonolo ea ts'ebetso le tlhokomelo, lintlha tsohle tse tsoang ho moreki li nahanela lehlakore.